Introduction:

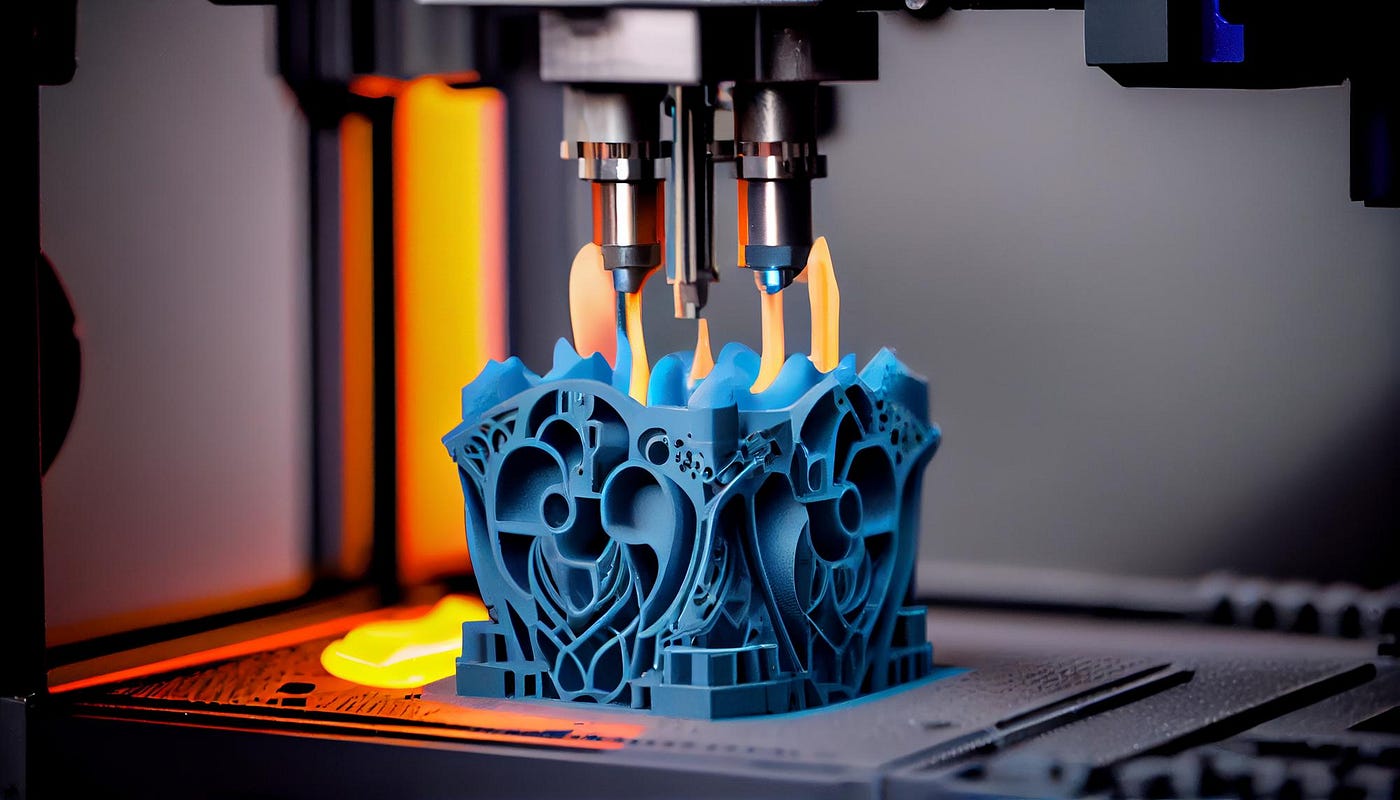

In the realm of manufacturing and innovation, 3D printing has emerged as a groundbreaking technology with the potential to revolutionize how we design, produce, and create objects. Also known as additive manufacturing, 3D printing enables the fabrication of three-dimensional objects layer by layer from digital designs. From customized medical implants to aerospace components and artistic creations, the possibilities of 3D printing are vast and far-reaching. In this exploration of the potential of 3D printing, we will delve into its origins, applications, advancements, benefits, and the profound impact it is poised to have on various industries and sectors.

Origins and Evolution:

The concept of 3D printing traces its roots back to the 1980s when Chuck Hull invented stereolithography, a process that uses UV light to solidify photopolymer resin layer by layer. Since then, 3D printing technology has evolved rapidly, with advancements in materials, printing methods, and software capabilities expanding the range of objects that can be produced. Today, 3D printing encompasses a wide range of techniques, including fused deposition modeling (FDM), selective laser sintering (SLS), and direct metal laser sintering (DMLS), each offering unique advantages and applications.

Applications Across Industries:

One of the key strengths of 3D printing is its versatility and applicability across diverse industries and sectors. In manufacturing, 3D printing is used to produce prototypes, tooling, and end-use parts with complex geometries and intricate designs. From automotive and aerospace to consumer electronics and fashion, manufacturers are leveraging 3D printing technology to reduce lead times, lower costs, and iterate designs more rapidly.

In the healthcare sector, 3D printing is revolutionizing patient care and medical device manufacturing. Medical professionals use 3D printing to produce patient-specific implants, prosthetics, and surgical guides tailored to individual anatomies. Additionally, researchers are exploring the potential of 3D bioprinting to create tissues, organs, and even pharmaceuticals, offering new avenues for regenerative medicine and personalized healthcare.

In architecture and construction, 3D printing is enabling the fabrication of complex building components, structures, and prototypes with unprecedented speed and precision. Large-scale 3D printers can create entire buildings using materials such as concrete, clay, or recycled plastics, reducing construction waste and environmental impact. Moreover, 3D printing allows architects and designers to explore innovative designs and construction techniques that were previously unfeasible with traditional methods.

Advancements and Innovations:

Advancements in materials science, printing technology, and software have expanded the capabilities of 3D printing and opened up new possibilities for innovation. Researchers are developing biocompatible and bioresorbable materials for medical applications, high-performance alloys for aerospace components, and sustainable materials for eco-friendly manufacturing. Moreover, advancements in multi-material printing and hybrid manufacturing techniques are enabling the fabrication of complex, multi-functional objects with diverse properties and functionalities.

Additionally, improvements in printing speed, resolution, and scalability are making 3D printing more accessible and cost-effective for a wider range of applications. Desktop 3D printers have become increasingly affordable and user-friendly, empowering individuals, makers, and small businesses to bring their ideas to life and customize products to their specific needs. Moreover, advancements in 3D scanning and software tools are simplifying the design process and enabling more intuitive and interactive workflows for creating 3D models.

Benefits of 3D Printing:

The benefits of 3D printing are manifold and extend beyond manufacturing and prototyping. One of the primary advantages of 3D printing is its ability to produce highly customized and personalized objects with minimal waste. Traditional manufacturing methods often involve subtractive processes that generate significant material waste, whereas 3D printing builds objects layer by layer, using only the material required for the final product.

Moreover, 3D printing enables rapid iteration and design optimization, allowing designers and engineers to quickly test and refine their ideas without the need for expensive tooling or molds. This iterative approach reduces time-to-market and enables faster innovation, giving businesses a competitive edge in today’s fast-paced market.

Furthermore, 3D printing offers greater design freedom and flexibility compared to traditional manufacturing methods. Complex geometries, intricate details, and customized features that would be challenging or impossible to produce with conventional techniques can be easily achieved with 3D printing. This design freedom enables designers to push the boundaries of creativity and explore new possibilities in product design and development.

Impact Across Industries and Sectors:

The potential impact of 3D printing across industries and sectors is profound and far-reaching. In manufacturing, 3D printing has the potential to decentralize production, enable on-demand manufacturing, and reduce supply chain dependencies. By eliminating the need for centralized production facilities and reducing transportation costs, 3D printing can enable more sustainable and resilient manufacturing ecosystems.

In healthcare, 3D printing is revolutionizing patient care and medical device manufacturing, offering personalized solutions for patients and providers. From patient-specific implants and prosthetics to anatomical models and surgical guides, 3D printing is enabling more precise and effective treatments while reducing costs and lead times.

In education and research, 3D printing is empowering students, educators, and researchers to explore concepts in science, engineering, and design in a hands-on and interactive way. By providing access to affordable and accessible 3D printing technology, schools, universities, and research institutions are fostering creativity, innovation, and problem-solving skills in the next generation of scientists, engineers, and makers.

Challenges and Considerations:

Despite its numerous benefits and opportunities, 3D printing also presents challenges and considerations that must be addressed to realize its full potential. One of the primary challenges is the limited range of materials available for 3D printing. While the range of 3D printing materials has expanded in recent years, there is still a need for more advanced materials with diverse properties and functionalities to enable broader applications in industries such as aerospace, automotive, and electronics.

Moreover, quality control, consistency, and repeatability are ongoing challenges in 3D printing, particularly for industrial-scale production. Variability in printing parameters, material properties, and environmental conditions can affect the quality and performance of printed parts, leading to defects, deviations, and inconsistencies. Ensuring consistent quality and reliability in 3D printing requires robust process control, monitoring, and validation procedures.

Furthermore, intellectual property (IP) protection and regulatory compliance are critical considerations in 3D printing, particularly in industries such as healthcare and aerospace where safety, security, and traceability are paramount. Protecting digital designs, enforcing licensing agreements, and preventing unauthorized copying and distribution of 3D-printed objects are ongoing challenges that require collaboration between industry stakeholders, policymakers, and regulatory agencies.

Conclusion:

In conclusion, 3D printing is a transformative technology with the potential to revolutionize manufacturing, healthcare, education, and beyond. From rapid prototyping and custom manufacturing to personalized medicine and sustainable design, 3D printing offers a wide range of benefits and opportunities for innovation. However, realizing the full potential of 3D printing requires addressing challenges such as material limitations, quality control, and IP protection while fostering collaboration, investment, and adoption across industries and sectors. As 3D printing continues to evolve and mature, it will play an increasingly important role in shaping the future of design, production, and creativity in the digital age.